What future for 3D printed glasses?

3D printing continues to flourish. With technological advancement, many companies have established themselves in this market which has many advantages. In recent years, 3D printed glasses have offered new perspectives to the optical sector. We take stock of their advantages and their promises.

3D printed glasses: 100% tailor-made?

3D printing promises to revolutionize the industry. In just a few hours, it is possible to automate the manufacturing of material parts with remarkable finish and solidity. A technology which therefore adapts perfectly to the needs of professionals in the optical industry. The speed of execution also makes it possible to offer tailor-made frames to customers. All they have to do is choose their frame via an application using artificial intelligence and virtual reality for fitting.

If these applications, during the first deployments, did not reflect reality, this is no longer the case. As mixed reality has evolved considerably, it now transforms virtual fitting to make it perfectly realistic.

Acuitis stores have succeeded in developing this service. Using a digital tablet, measurements of the customer's face are taken and therefore make it possible to present several models of customizable frames (shapes, temples, colors)

What are the advantages of this offer?

In addition to being able to make each model unique, 3D printing offers new perspectives for the manufacture of glasses. Printed with polyamide dust and based on each customer's measurements, their manufacturing does not create waste, which is a big step in an industry keen to diversify its materials and reduce its carbon footprint .

In terms of pure manufacturing, 3D printing allows the creation of extremely robust frames, which will satisfy both parents and the clumsiest adults! Indeed, 3D printed glasses can be twisted without breaking and suffer very little damage from shocks.

A prosperous future for the sector?

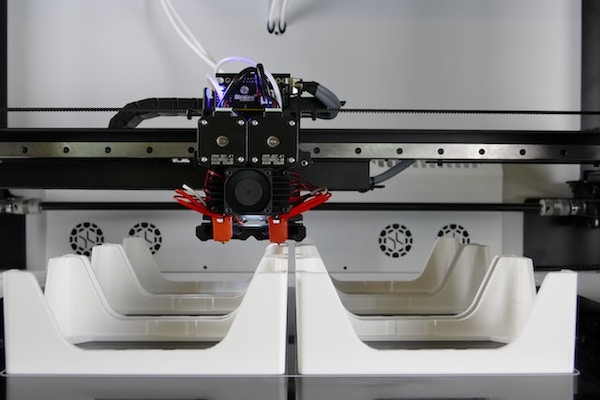

If sales of 3D printed glasses only represent around 10% of stores that offer it, its various advantages could lead to their rapid development. In return, it will be necessary to strengthen partnerships with companies equipped with 3D printers. The investment is therefore not that heavy but it will be necessary to redefine an organization to work with partners who are not necessarily familiar with the constraints of the optical sector. Nothing insurmountable though.

The future of 3D printing glasses will mainly depend on the way in which the sector promotes them, without discrediting historical manufacturers and craftsmen who work with other materials, other manufacturing processes, and which must not be discredited by this new way of working.